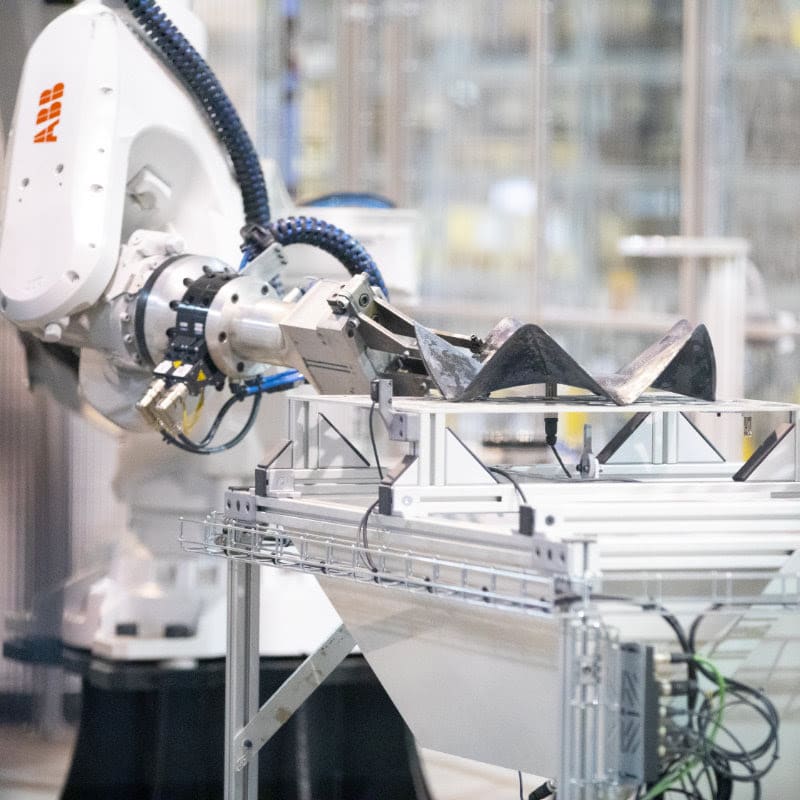

Fifty employees and 40 robots work over two shifts to develop and manufacture the most vital parts of agricultural machinery; the ones that go into the ground and get the job done. It’s at this stage where a real difference can be made in terms of the machinery’s performance, operating costs and durability.

Väderstad has launched its new Materials Technology Lab, as it takes a further step in securing its position as the world’s leading supplier of wear parts for agricultural machinery. This lab improves Väderstad’s control over the design and performance of the wear parts. It also opens up greater opportunities to develop materials and methods in a stable and efficient manufacturing process.

Read more about this in Parts News Extra